There are many touch points for a package before reaching your end customer, so make sure the packaging holds up through all of these touchpoints.

The external packaging should only act as a barrier to protect the internal goods from weather and damage during transit. It's the internal packaging that is the most crucial protection barrier.

If repackaging is required during transit, this will cause extended delays to your end customer. It will also void you of any transit protection coverage you may have paid for.

Here are some key tips to follow to ensure things reach your end customer safe and intact!

Key tips for packaging.

- Choose well. Choose strong, fitting and durable packaging based on product type not journey type.

- Void fill. Don't leave dead space in the satchel or carton.

- Layer internally. Protect your items as much as possible internally, the more protective layers the better.

- Don't tape items together. Boxes and items should not be taped together. Each individual item requires it's own shipping label. Items that have been taped together will not be covered in the event it comes apart and goes missing.

- Don't rely on fragile stickers. Goods are handled manually very minimally, so make sure your packaging does the work don't rely on fragile stickers as machines don't capture these.

- Add Transit Protection. Cover yourself for those dissapointing scenarios.

Satchels.

Satchels are a very cost-effective option, just remember a few things.

- No fragile, sharps, or liquids. These are not suitable to travel in a satchel, use carton instead.

- Don't over pack. Trying to fit too much in a satchel might cause it too burst open during transit which means the contents may get lost.

- Seal shut securely. Fold over the satchel if the cnotents don't fill the entire satchel space. Using extra tape will ensure any un-stuck folds don't get stuck to anything else and tear open.

Boxes and Cartons.

The carton is an external barrier only and needs to be strong and durable to hold up during travel. Remember, adequate internal packaging is resposible for protecting what's inside.

- Don't overload. Make sure the carton strong enough to carry the weight of the goods inside.

- Choose the right size. As you're charged for the greater of actual or volumetric weight, try not to leave any dead space inside the carton.

- Void fill. Pack dead space is filled with a void-fill material such as bubble wrap, newspaper, or air pillows to stop things from moving around inside.

- Seal shut securely. Use durable and water-resistant tape incase the box comes into contact with wet weather.

- Label each box. Don't tape boxes together as each individual box requires it's own label and is measured based on cubic size.

Fragile Items.

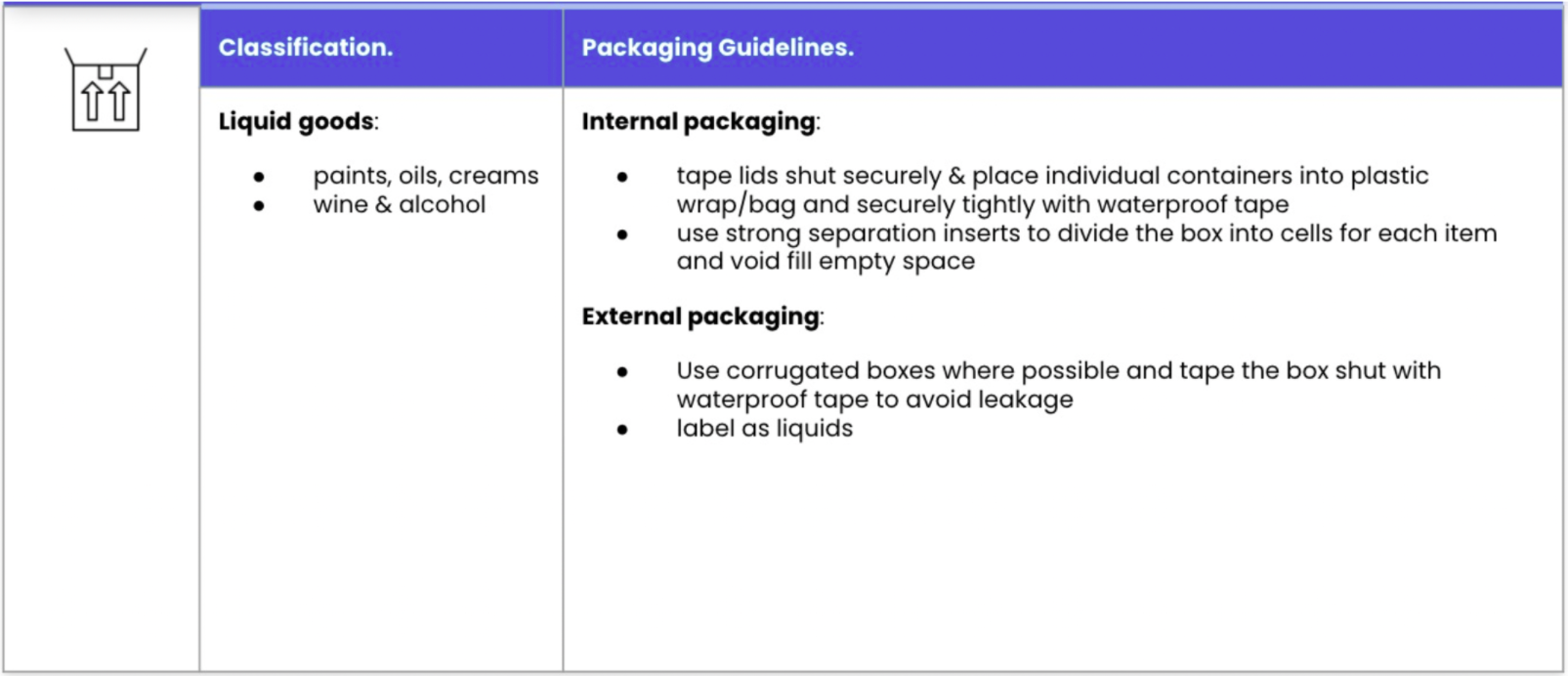

When sending fragile items it's absolutely crucial to ensure the goods are sufficiently packaged. Goods will travel through several automatic sortation devices and machines can't read fragile labels. Below is a list of guidelines below based on product type to help.

Pallets and Heavy Goods.

You'll be required to palletise heavy and bulky goods as these can't be manually handled. Pallets require a forklift when handling goods and a special tail-lift vehicle to transport the goods.

Goods over 30kg should be placed on a skid or pallet for the truck before arrival otherwise you will incur fees to have them palletise it for you.

Here are some tips for proper palletisation:

- Stack within the dimensions of the pallet and don't stack pallets too high.

- Keep pallets level & stackable. Carriers will not accept pallets with over-hanging goods and you will have to pay a surcharge if your pallet isn’t stackable.

- Stretch wrap your pallets. Use pallet wrap or at least two straps from both sides to hold items in place. Strapping and wrapping should include the pallet itself.

- Label pallets clearly. Affix to the side, not the top as another pallet may be stacked on top of yours.

Labelling.

- Label correctly. Remove any old labels and ensure the correct label can be read properly.

- Don't cover or crease. No tape should placed over the barcodes as this will affect it being read. Packages will not be accepted if the label cannot be scanned.

- Dangerous goods. Ensure all DG are labelled correctly and signed off by a certified DG person. Do not ship DG with carriers that are not accpeting of those DG.